Water Bore Screens & Well Screens

At CWS, we specialise in the design and manufacture of wedge wire screens for water well drilling applications. Our founders have first-hand experience in water well drilling and have a deep understanding of the characteristics that make a quality bore screen. We are members of the Australian Drilling Industry Association and are proud to support water well drillers with the supply of quality products across Australia and abroad.

Water well screens or bore screens, as they are commonly referred to, act as intake filters or strainers in water wells/bores that are constructed in unconsolidated aquifers. The screen allows the transmission of water from the aquifer into the bore whilst retaining the sediment and supporting the unconsolidated aquifer structure. Wedge wire is ideal for this application as the v-shaped wire is self-cleaning and limits clogging as the water and fines pass through the screen.

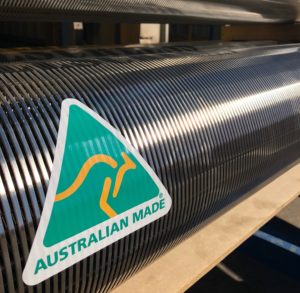

Through purposeful design, use of quality materials and semi-automated manufacturing processes, CWS produces water well screens that deliver longevity and support efficient and effective water bore performance.

Specifying your water bore screen

When you request a quote for a CWS bore screen, it’s important to have the following information on-hand so we can match the screen design to your unique application.

Depth setting

The position of the screen in the well is a crucial consideration when engineering the screen. This, in combination with aperture selection helps us to determine the appropriate screen design to handle the potential collapse pressure that may exist within the bore.

Effective screen length

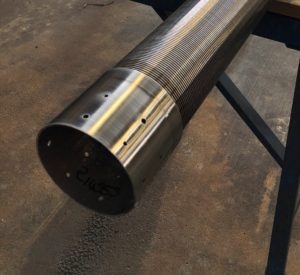

CWS can offer effective single screen lengths from 500mm up to 6000mm.The effective screen length refers to the overall length of the wedge wire portion of the screen. This is the portion of the screen with open area which allows water transmission. It excludes any attachments that may be fitted to the screen.

Aperture (slot)

CWS can offer aperture settings from 0.25mm (0.010″) up to 10.00mm. Our screen machines are designed to achieve precise aperture accuracy, typically within a tolerance of +/-0.05mm (0.002″). We can also offer variable aperture settings on a single screen to match the unique conditions within the aquifer. To assist with aperture selection, CWS can offer a sieve analysis service that is performed to the standards recognised by the ADIA.

Material

CWS offer screens made from 304 and 316 grade stainless steel. In particularly abrasive or hard water applications, 316 material may provide better wear characteristics and increase the effective life of the screen.

Diameter (ID or OD)

At CWS, we have an extensive catalogue of tooling to produce a wide range of water well screen diameters. We offer screens from 52.4mm ID up to 24″ OD. We also offer screen fittings that match most API stainless casing and PVC casing sizes.

Water bore screen fittings and attachments

CWS offers a wide range of screen fittings including:

- Standard gauge and over-sized beveled weld rings;

- Male and female PVC casing adaptors;

- Male and female threaded couplings;

- Concentric reducers;

- K-Packer/J-Latch sealing packers, and;

- Base plates/end caps.

Designing your water bore screen

With this information, we can design the screen to suit the well. By selecting the appropriate wedge wire and support rod combination for your application, we engineer the screen to maximise collapse pressure, transmission capacity and tensile strength. This ensures that every CWS well screen is fit for purpose, every time.

For more information on CWS water well screens, submit an enquiry via the button below or give us a call.

To learn more about selecting the right screen for your well, head to the ADIA website and consult the Minimum Construction Requirements for Water Bores in Australia.

“As one of the longest standing drilling companies in Australia, you cannot beat Condamine Wellscreens for Quality, Service and Price. When I put bore screen 100s of metres underground, I want to know it’s still going to be there in 60 years and won’t corrode out in 10. CWS backs my promise of performance to customers. The price is extremely good value for the peace of mind they provide and the ease of dealings with them.”

jim devlin, owner, new britain drillers, png