Flat & Curved Wedge Wire Screens

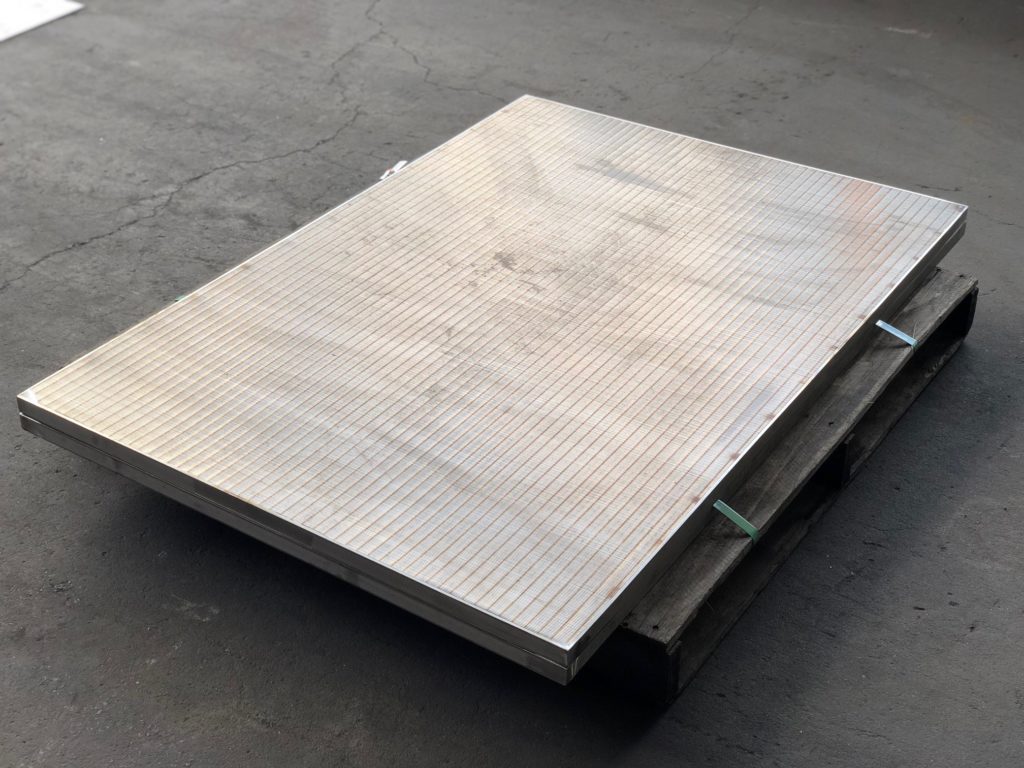

CWS offers a range of flat and curved wedge wire screens for a variety of applications. Our wedge wire panels can be found across Australia and New Zealand in coal mining, hard rock mineral processing, quarrying, wastewater treatment and a range of other dewatering and sizing applications. We offer a wide range of wedge wire profiles and support rods to suit customer applications. All CWS screens are configured to effectively leverage wear characteristics, optimise structural strength and maximise transmission (flow) capacity.

We specialise in the manufacture of:

- custom-made screen media inserts for static and vibratory decks;

- custom-made dewatering screens with bespoke mounting framework, and;

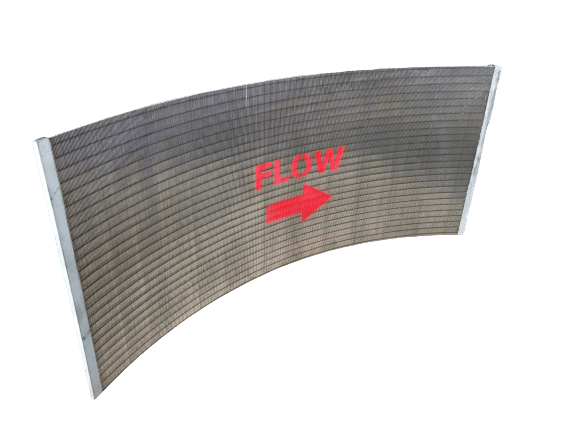

- custom-made sieve bend screens (DMS screens) to suit existing sieve bend housings.

Screens may be manufactured to customer-supplied engineering drawings on request.

Optimised for a longer service life.

Stainless steel wedge wire is an ideal material for dewatering, screening and desliming applications due to its high resistance to wear in corrosive and abrasive environments. We utilise specific wedge wire profiles with a shallow relief angle as standard for high-wear applications which maximises the effective lifespan of the wire. On site, this translates to a longer service life, less screen media turnover and down time, and greater overall efficiency in the screening process. For highly corrosive applications, screen panels may be chrome plated to further enhance wear characteristics.

Designed to maximise transmission capacity and reduce pegging and blinding.

Wedge wire screens offer a high effective open area which maximises the transmission capacity of the screen, delivering superior flow in dewatering applications. Due to its unique tapered profile, wedge wire also reduces the risk of pegging (where particles become lodged in the screen aperture) and blinding (where sticky particles bind to the screen, resulting in bridging across the screen aperture), reducing downtime associated with cleaning and maintenance and delivering a more efficient screening process.

Sieve bend screens (DSM screens)

CWS offer sieve bend or DSM screens to suit existing screen housings on request. We have the capability to deliver a wide range of sizes, apertures and arcs and can provide specialised mounting hardware on request to ensure that the screen seamlessly integrates with your existing equipment.

We can offer cross-flow (where direction of flow is perpendicular to the screen aperture) or with-flow (where direction of flow is parallel to the screen aperture) on request. In cross-flow configurations, the wedge wire is positioned at such an angle that the leading edge cuts against the direction of flow, providing effective separation of solids from liquids. As the screen wears over time, it may be rotated 180° which presents the opposite edge of the wire to the direction of flow, thereby extending the effective service life of the screen.

For more information on CWS flat and curved wedge wire screens, submit an enqiury via the button below or give us a call.

Benefits of CWS Flat & Curved Wedge Wire Screens

High open area for effective flow.

Superior wear characteristics for a longer service life.

Precise aperture settings deliver effective screening.

Minimise pegging and blinding.

Configured to suit your specific requirements.

Competitively priced and promptly supplied.

“The team at Condamine Wellscreens offer good product consistently with good service. I am very satisfied with them and have never had an issue. Competitor product just isn’t as good for what we do.”

colin gray, branch manager, cove engineering